Simulations Point the Way to Next-Generation SiC Power Packaging

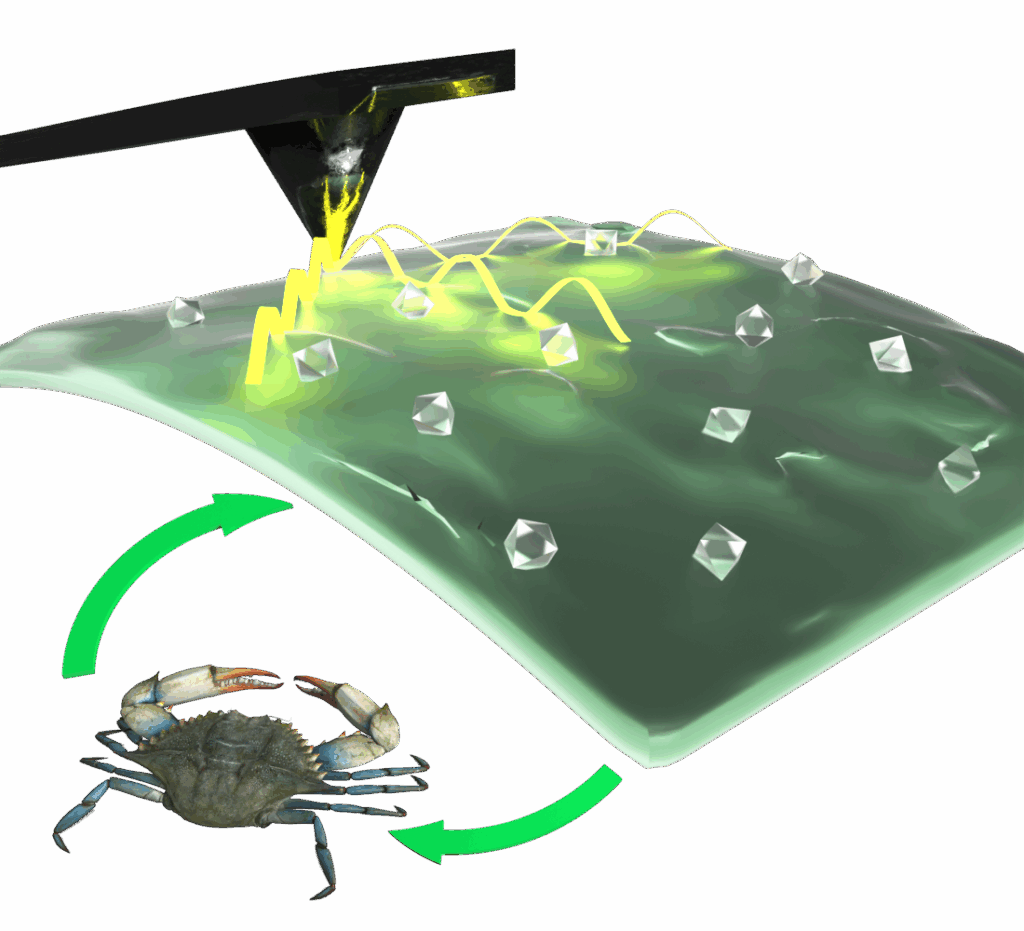

A new study led by researchers at Ca’ Foscari University of Venice, in collaboration with ON Semiconductor, University of Naples Federico II, and University of Applied Sciences Kempten, has unveiled a powerful digital approach to designing the future of high-efficiency power electronics. The work, recently accepted for publication in the IEEE Open Journal of Power Electronics, is titled “Multi-Physics Simulations of a 1.2 kV Embedded SiC Prepackage”. The research team includes Saimir Frroku, Ankit Bhushan Sharma, Pierfrancesco Fadini, Klaus Neumaier, Andrea Irace, Till Huesgen, and Giovanni A. Salvatore, who coordinated the study at Ca’ Foscari’s Department of Molecular Sciences and Nanosystems. A New Era for Power Device Packaging Wide-bandgap (WBG) semiconductors such as silicon carbide (SiC) are transforming power electronics thanks to their ability to operate at higher voltages, temperatures, and switching frequencies than traditional silicon. Yet, packaging remains a critical bottleneck—how these chips are physically mounted, cooled, and electrically connected determines the true performance and reliability of a power module. Embedding the SiC chips directly into an insulating substrate represents a breakthrough approach. By eliminating bulky wire bonds and reducing parasitic inductances, embedded packages enable faster and cleaner switching, boosting efficiency and compactness. However, questions of mechanical reliability and heat management have persisted. Digital Twins for Real-World Reliability The Ca’ Foscari team tackled these challenges through multi-physics finite-element simulations, virtually reconstructing a “prepackage” containing two 1.2 kV SiC MOSFETs and exploring different commercial substrates—alumina, silicon nitride, aluminum nitride, and insulated metal boards (IMS). Their thermomechanical “digital twin” captured how heat and mechanical stress propagate during manufacturing and operation, allowing the team to pinpoint design weaknesses long before physical prototyping. Using a Pareto-based optimization, they identified aluminum nitride (AlN) as the most balanced substrate, achieving a thermal resistance of just 0.27 K/W and low mechanical strain levels. Engineering Smarter Structures The simulations also revealed how to strengthen the package against long-term mechanical fatigue. Replacing the traditional solid copper top contact with a pillar-like interconnect geometry reduced creep strain in the silver sintering layer by up to fourfold—a major leap for reliability. Even the cooling rate during manufacturing proved to be a critical factor: above a certain threshold (around 40 K/min), creep deformation virtually disappears, leaving only reversible plastic strain. This insight offers a new lever for process control and reliability enhancement. Toward Scalable, High-Frequency Power Modules By virtually paralleling four optimized prepackages, the researchers demonstrated a compact power module with only 3 nH of stray inductance, suitable for high-frequency, high-efficiency power conversion—crucial for electric vehicles, renewable-energy systems, and data-center power supplies. “These simulations allow us to accelerate innovation while reducing costly trial-and-error fabrication,” explains Giovanni A. Salvatore, senior author of the study. “Digital modeling provides predictive insights into reliability and performance, helping us design the next generation of power modules that are both efficient and robust.” From Simulation to Sustainable Energy Systems The findings open new perspectives for integrating wide-bandgap semiconductors into compact, thermally stable, and manufacturable modules—an essential step toward electrified mobility and renewable-powered grids. The team’s work exemplifies how virtual engineering and experimental design can converge to drive sustainable innovation in advanced electronics. The full article is available at: https://ieeexplore.ieee.org/document/11224018. All image rights and copyrights are reserved by IEEE.

Simulations Point the Way to Next-Generation SiC Power Packaging Read More »